Guide

What is Microcement?

Microcement, or Micro cement is a decorative coating system, that creates a seamless, modern appearance.

It is also known as microconcrete or microtopping, and it’s applied in thin several thin layers, creating a flawless backdrop for contemporary interiors. It has gained popularity in the last few years, due to its aesthetic appeal and water-resistant quality, as it can be applied on various surfaces, such as flooring, worktop, walls and ceilings, allowing for excellent customisation when it comes to decorating. There are many Microcement suppliers in the UK, and the list is growing. This also applies for the number of Microcement installers.

Composition and Application

The different components of microcement are various blends of cement, polymers and colour pigments.

These components are applied on substrates, following a strict order, after adequate surface preparation. It can be applied on virtually any surface, such as countertops, floors, walls and even furniture. It’s the best material for complicated surfaces, such as curvatures, as the consistency of the material allows for great flexibility. Once all layers are applied, it’s 2 -3 millimetres thick, and finishes with a durable resin protector, for water resistance.

The steps for applying microcement generally include:

Surface Preparation: The existing surface is cleaned, repaired, and primed to ensure proper adhesion.

Base Coat Application: A base layer is applied to create a smooth foundation.

Microcement Coats: The different components of Microcement are applied.

Sanding: The surface is sanded between to get rid of any excess product, and create a smooth surface for the sealer.

Sealing: A protective sealer is applied to enhance durability and provide a waterproof barrier.

To see the full tutorial for the application of our Microcement Kits, click on the link here!

Advantages of Microcement

Microcement has a wide range of advantages, a lot of which can be beneficial for residential and commercial properties.

Seamless Finish:

A seamless finish is one of the qualities that made microcement the popular material that is today. One of the most notable features is its ability to create a seamless, continuous surface without the need for joints or grout lines. This gives a clean, contemporary look that is easy to maintain.

Versatility:

It can be applied to a variety of substrates, including concrete, tile, plaster, and drywall, making it suitable for renovations and new constructions alike.

Durability:

Despite its thin application, microcement is remarkably durable and resistant to daily wear and tear.

Waterproof:

When properly sealed, microcement is water-resistant, making it ideal for bathrooms and kitchens.

Customisable:

Available in a wide range of colours and finishes, microcement can be tailored to fit any design aesthetic, from industrial to minimalist.

Design Flexibility

Microcement is favoured by designers and architects for its aesthetic flexibility. It can mimic various textures, such as polished concrete, marble, or stone, allowing for creative expression in interior and exterior designs. Additionally, its ability to adhere to different surfaces means it can be used in innovative ways, from flooring to accent walls and custom furniture.

Maintenance and Longevity

Maintaining microcement surfaces is relatively straightforward. Regular cleaning with mild detergents and water is usually sufficient to keep it looking new. The durability and low maintenance requirements make it an economical choice over time. However, it is advisable to periodically reapply the protective sealer to maintain its waterproof properties and prolong its lifespan.

An Eco-Friendly Option

Microcement is also considered an environmentally friendly option. Its application involves less material compared to traditional cement overlays, reducing waste. Moreover, its long lifespan and low maintenance reduce the need for frequent replacements and repairs, contributing to sustainability.

Conclusion

Microcement is a modern, versatile, and durable material that offers a sleek, seamless finish for various surfaces. Its adaptability, range of finishes, and ease of maintenance make it a popular choice for contemporary design projects. Whether for residential or commercial use, microcement provides a stylish and practical solution for creating beautiful, enduring spaces.

10 Advantages of Microcement

Microcement has become a staple as a versatile finish, in contemporary interior design.

It’s cement-based coating, that provides a seamless durable finish which can be customised with different colours, textures and finishes.

Interested in making Microcement part of your interiors?

Here are 10 key advantages, why you should consider Microcement for your home.

1. It gives you a seamless finish

The continuous, seamless finish that can be used across all different surfaces, from floor to ceiling, made Microcement one of the most popular design solutions in contemporary interior design. Not only is it visually appealing, but it will also save you the trouble of having to clean dirty grout lines and joints.

2. It is versatile

Choosing Microcement, also means choosing versatility. It can be applied on virtually any surface and substrate, so long as the right primer is used. The decorative coat of Microcement also allows it to be customised in the same way Venetian plaster can. This means being able to create fully bespoke finishes for floors, walls and wet room areas by choosing the colour, texture and finish!

3. It is durable

Due to its components, a high-quality Microcement can withstand the daily wear and tear of the home, ensuring a long-lasting finish that maintains its appearance over time. The anticrack system installed as part of the first coat prevents cracking, and the resin-protecting coat gives it a level of resistance that not many decorative finishes have.

4. It's water-resistant

Microcement is a water-resistant finish, suitable for flooring, worktops and bathrooms. Thanks to its sealing coat, when applied correctly, the surface will stay resistant to the growth of mould and milder, making a practical and hygienic finish in any space exposed to water and humidity.

5. It offers great aesthetic flexibility

The customisable aspects of Microcement allow for it to be used as part of many different design schemes. The unique textures, from smooth to more rough or rustic finishes complement many different interior styles. The decorative coat can be coloured to any tone, which will blend in seamlessly with different types of home decor, from modern and minimalist, to industrial looks.

6. It’s quick to install

Given that Microcement can be applied over existing surfaces, such as tiles, the installation process is relatively faster, compared to other floor and wall finishes.

This reduces the overall cost, and minimises the project timeline, making Microcement an efficient choice for renovations and new builds alike.

7. It’s low-maintenance

Microcement is a material that is relatively easy to maintain. Regular cleaning with mild detergent

Microcement requires minimal maintenance to keep it looking new. Regular cleaning with mild detergents and water is usually sufficient to maintain its appearance. Unlike other materials that may require periodic resealing or refinishing, microcement's durable finish and resistance to stains and spills make it a low-maintenance option.

8. It’s an eco-friendly material

Compared to traditional cement overlays, Microcement is a relatively thin coating system with a maximum thickness of around 2-3mm. This means opting for Microcement can reduce waste, and require overall less material for the same coverage. Its long lifespan and durability ensure low maintenance and fewer needs for replacements and repairs over time.

9. It’s heat-resistant

The practicality of Microcement doesn’t stop at water resistance, it is also resistant to high temperatures.

Its heat resistance ensures its suitability for areas exposed to heat, such as kitchens and fireplaces, without any cracking or discolouration. Being able to withstand these temperature fluctuations means that the finish can last for a long time, with proper care and maintenance.

10. It increases the property value

As with most Venetian plaster-type products, Microcement becomes part of the building which means that this high-quality finish can increase its value.

The modern, sleek appearance it offers can appeal to potential buyers and tenants, making the property an overall more attractive choice on the property market. It’s important to note that materials with this level of practical and aesthetic appeal can provide a significant return on investment, due to the excellent combination of functionality and aesthetics.

These are just the most important advantages listed, but each one holds a different level of importance for different types of people and projects. But opting for Microcement means benefitting from advantages that from all of the above, or advantages that we have not even listed such as its compatibility with underfloor heating.

Applications of Microcement

Not many people know just how many surfaces can Microcement be applied on. This seamless and durable finish is not only beautiful to look at, but it also offers a practical solution who want to create a cohesive feel and need a uniform look across multiple surfaces. As it offers a water-resistant finish, it can be applied to almost any space where most decorative materials would be off-limits, such as areas exposed to high temperature and humidity.

So which are the most popular applications of Microcement around the home?

1.Floors

Choosing a seamless, and customisable finish for flooring that provides a continuous look without any joints, is becoming more and more popular as open-space solutions are on the rise for residential homes, and commercial developments.

Microcement provides an aesthetic and practical solution that is bespoke and made to fit any project, and offers plenty of choices for those who wish to customise a finish their own way.

2.Walls

Microcement is known for the concrete-like finish that can be created with it, which tends to be popular for modern and industrial-style interiors, especially in commercial buildings. It is a material, however, which can be pushed much further than that. When it comes to intricate patterns, such as a marble finish, microcement is a great option for feature walls.

Depending on where the finish will be applied, we recommend including the anti-crack system. It is optional areas where the Microcement is not in direct contact with water, but it is a must to include for any project concerning flooring and wet room areas.

3.Bathrooms

If you ever saw a photo of a seamless, modern bathroom, you can imagine what Microcement looks like in these spaces. A lot of people compare it to the Tadelakt finish, but when it comes to technical details, the two are not the same.

Microcement is a meticulously developed material that can ensure a water-resistant and durable finish, even with its relatively thin coating. It includes an anti-crack system, and a resin-protecting coat, which ensures the water can’t penetrate and damage the surface. This makes Microcement a practical and aesthetically pleasing material, that can be used on multiple surfaces across the bathroom, from the shower area to the worktops and cabinets.

If you are interested in having Microcement installed in your bathroom, be sure to ask for a sample from your applicator, without sample kits!

4.Kitchens

When it comes to the kitchen, applying Microcement doesn’t have to stop at the floors and walls, it’s a great idea to have it installed on the worktops, shelves and splashbacks, for a continuous finish!

It provides a seamless and easy-to-clean surface on countertops and worktops, with it bespoke colours and protectors so your kitchen can be practical and beautiful at the same time.

5.Furniture and Custom Designs

When used on larger surfaces in the home, some people feel inspired to have a matching finish on various elements around the home, such as joinery or shelves. Due to the nature of Microcement, as a material that is applied from a container directly on the surface, it offers the option to create custom solutions for any surface you’d like to cover.

Some of the most popular ones include staircases and cabinetry with shelves and countertops. It’s a wonderful option for those who want their home interiors to feel cohesive and modern, to provide the perfect backdrop for their day-to-day lives.

If you are interested in how Microcement looks when it's being applied, check the full application video for our Continuo Microcement here!

What are the Advantages of Choosing Microcement for Different Surfaces?

There are a few reasons why Microcement is becoming more and more popular in the world of Interior Design, and here are just a few!

The Seamless Finish: Microcement creates a smooth, joint-free surface that is easy to clean and maintain.

The Durability: It is resistant to wear, impact, and chemical damage, making it suitable for different surfaces.

The Versatility: It can be applied to various surfaces and tailored to different textures and colours.

The Water-Resistance: It is ideal for wet areas like bathrooms, floors and kitchens when properly sealed.

The Quick Installation Process: It can be applied over existing surfaces, reducing the need for extensive demolition and speeding up renovation projects.

Conclusion

Due to the nature of microcement, it can be a practical and versatile product to choose for many different surfaces for a seamless, bespoke finish.

Its adaptability ensures it meets aesthetic and functional requirements, which is what made it popular for different areas in the home, from flooring to worktops, and showers.

Advantages of Microcement Over Tiles

When it comes to surface finishes that are durable and resistant, tiles and microcement always come up amongst the most popular options in interior design.

Tiles have been around for a while, which means that for a long time, they were thought of as the standard solution, especially for wet room areas. In recent years, however, Microcement seems to win over a growing portion of homeowners, designers and interior enthusiasts, due to its seamless finish and versatility.

But what exactly are the advantages of Microcement over tiles? Let’s take a look at 3 major factors of comparison; features, application and cost.

Features

Seamless Finish

One of the key features that made Microcement popular was first and foremost, the seamless uniform finish, which can be applied over any surface, from walls to floors, and even furniture. This seamless look can create a beautiful, cohesive space with a luxurious feel only bespoke finishes can offer.

Durability

Microcement is a wonderful option as a decorative material, that is also functional and durable. Depending on the type of Microcement you use, the durability and resistance can differ, but this multi-component system boasts competitive resistance to daily wear and tear, due to its resin finishing coat.

Aesthetic Versatility

The versatility of the material impresses everyone who finds out about it. Aside from the range of neutral and bold colour selections, we have available at Impera Italia, we also offer a colour match service. This means that you can have the material in any colour you’d like, in a matt satin or glossy finish.

To add an extra layer of customization, Microcement’s decorative coat is a material that can achieve different textures or none at all. Whether you choose an ultra-smooth or a slightly rougher texture, it will not impact the durability or the practical maintenance of the finish.

Minimal Environmental Impact

For those concerned with the environmental impact of the material, and who want to minimise the waste occurring during the renovation process, Microcement is a considerably better choice compared to tiles.

As Mictrocement can be applied over the existing substrate, saving you the cost and time of having to remove and dispose of it.

Our supplier for Microcement, San Marco, is known for its excellent standards when it comes to creating eco-friendly materials, ensuring that any product they manufacture has the least amount of negative effects on the environment.

Application

The application of microcement, as a multi-layer coating system is a complex process, and should only be done by professionals. Compared to tiles, the cost is very competitive, especially when we calculate how much it would cost to remove any old surface covering. Microcement is a relatively easy solution to renovate large areas, without extensive surface preparation, reducing the hassle that renovations can mean sometimes.

Depending on the type of Microcement you choose, they can be applied on both residential and commercial properties, where a stylish, seamless look is required.

For those who are concerned about whether our Microcement options would be suitable for their project, we recommend emailing to sales@imperaitalia.com , and getting professional advice from our experts!

If you are interested in learning to apply Microcement, check out beginner and advanced courses!

Cost

Depending on where the project is, and how large it is, the installation cost can vary wildly for Microcement. As the framework of applicators is not as established yet for this relatively new decorative material, it requires some research to ensure you get the right people for the job.

At Impera Italia, we are happy to say we have decades of experience and insights into the industry and can guide our customers to the right place. Our Brand Ambassadors are successful professionals with their own businesses, whose work we trust and recommend to anyone who needs an installer.

Aside from the initial cost, Microcement can be a cost-effective option given its durability and simple maintenance requirements. It can be applied over existing surfaces, which means that it will save you the trouble and the cost of having to remove the previous substrate, saving you the cost of any extensive surface preparation.

Conclusion

Whether Microcement is the right choice for you, will depend entirely on on what your priorities are for your project.

Microcement enjoys a strong advantage over tiles when it comes to versatility, due to the nature of the products. It’s the best option for a bespoke design, and for anyone who wants to enjoy its customisable features.

Whilst regular maintenance can go a long way, it’s a good idea to reseal the finish periodically, to ensure it maintains its original look. However, it will save you the trouble of dirty grout lines, and dirt accumulating in the crevices.

Its seamless look can present a great solution for those who want a simple uniform look that creates a cohesive look for surfaces, from flooring to furniture, ensuring a consistent finish everywhere you look.

Differences Between Microcement & Polished Concrete

Often confused when it comes to floor finishes, Microcement and polished concrete may seem similar to the untrained eye, but there are some important differences when it comes to their technical details, installation process and purpose.

To help you understand the differences, we gathered the 7 most important factors to consider when choosing between the two.

1.Composition and Structure

Microcement

Composition:Microcement is composed of polymers, aggregates and pigments, sealed with a resin protector. The different components are applied in thin coats, the final thickness usually staying around 2-3mm.

Structure: The material has different parts that are layered on top of each other, each having its own purpose in creating a durable and aesthetically pleasing finish. Microcement can be applied over existing surfaces such as tiles, and wood.

Polished Concrete

Composition: Polished concrete is a more traditional and simple finish, made from concrete, which consists of cement, aggregates such as gravel, crushed or stone) and water.

Structure:The finish is achieved by polishing a solid, concrete slab to achieve a smooth and shiny finish.

2.Application Process

Microcement

Surface Preparation: The existing surface is cleaned, repaired, and primed.

Layering: Microcement coating is applied layer by layer, each left to dry before the next one is applied.

Sealing: A protective sealer is applied to ensure the surface will resistant to water, and daily wear-and-tear, enhancing its durability.

Polished Concrete

Initial Pouring: An existing concrete slab can be used, or a new slab poured.

Grinding: The surface needs to be smoothened, and grounded down using progressively finer diamond abrasives.

Polishing: The concrete is polished to the desired level of sheen, often involving multiple passes.

Sealing: To seal the surface, a densifier and sealant is applied over it to protect and enhance the shine.

3.Thickness and Weight

Microcement

Thickness: Microcement is a relatively thin layer, the overall thickness remaining around 2-3mm, which is very practical when applied over existing surfaces.

Weight: It’s a very light material, especially compared to traditional concrete, which makes it a wonderful choice for areas where the weight of the material is a concern.

Polished Concrete

Thickness: Polished concrete is a much heavier material, but its exact weight depends on the thickness of th econcrete slab, usually several inches.

Weight: Heavier than most materials used for similar purposes.

4.Flexibility and Versatility

Microcement

Flexibility: Microcement, especially with anti-crack system applied, provides an exceptional flexibility and adapt easily to changes in the substrate. It can be applied on almost any surface, both vertical and horizontal, such as furniture, countertops or flooring.

Versatility: It’s available is virtually any colour, given it’s separate decorative component that is bespoke coloured for each project. The textures and finishes can also very, making it an excellent design choice to blend in with the decor.

Polished Concrete

Flexibility: It can only be applied on horizontal surfaces, such as floors, in large open plan spaces.

Versatility: Mostly available in natural concrete colours, but dyes and stains can be added fot some colour.

5.Durability and Maintenance

Microcement

Durability: When properly sealed, it’s resistant to water and daily-wear-and-tear, but the scope of durability can vary between different Microcement, therefore, it’s always best to check with the supplier.

Maintenance: It requires nothing more than regular cleaning with mild detergents, and periodic resealing to keep its appearance up to date, for many years.

Polished Concrete

Durability: It’s one of the most durable materials, often used for commercial spaces and parking areas, it is resistant to heavy traffic and impacts. It is also highly resistant to water and stained, if properly sealed.

Maintenance: With regular cleaning and occasional resealing, it can last for a very long time, even with minimal maintenance.

6.Aesthetic Appeal

Microcement

Finish: Can be smooth or textured, with a matt or glossy finish.

Customization: Microcement is one of the best materials for those we have very specific design choices, as it’s possible to create a wide range of textures and finishes, which can be made to order in virtually any colour. It’s an excellent product for stylish design choices, fitting in perfectly with any decor style from modern to rustic.

Polished Concrete

Finish: Typically, smooth and glossy, with a natural, industrial look.

Customization: Very limited when it comes to bespoke options, it more or less offers the same look and feel, but can be customised for some additional colour.

7.Installation Time and Cost

Microcement

Installation Time: It’s a relatively fast application, as the different coats can be applied on top of existing surfaces in very thin layers.

Cost: Different Microcements have different prices, but due the the minimal preparation it requires, the price is very competitive when it comes to durable and water resistant surface finishes.

Polished Concrete

Installation Time: It takes a significant time to to install, due to the different slabs needing to be poured and cured.

Cost: As it’s a more labour intensive application, it can be a more expensive due to the different grinding and polishing processes.

Conclusion

Both polished concrete and microcement can excellent choices for a durable and stylish finishes, but the level of durability and customization varies for each. Therefore, they serve different purposes.

Microcement is the best option for those looking to customize their finishes to the maximum, whilst saving time and cost during the renovation process.

Polished concrete is suitable for project where extreme durability is required, and a finish that is fit for the industrial environment.

Impera's 2 types of Coating

| Continuo Microcement | All Over Micro Coating | |

|---|---|---|

| Components | 2-Part (Mixing Required) | Single component (Ready to apply) |

| Layers | 8 | 5 |

| Primer required | Yes | No |

| Key Differences | The continuo system requires a set of scales. This is due to most components needing to be measured, in order to mix accurate quantities. The additional step of applying the LINK coat, adds time to the overall application. | All Over was designed with the intention of being easier, and faster to apply, with the goal of being single component. This avoids the use of powders, as well as weighing scales. This results in the additional benefits of a reduced application time, as well as less wastage, as any left overs can simply be covered up and kept for future projects. |

| Application Difficulty | 5. Specialist coating for professionals | 5. Specialist coating for professionals |

| Water Resistant | Yes | Yes |

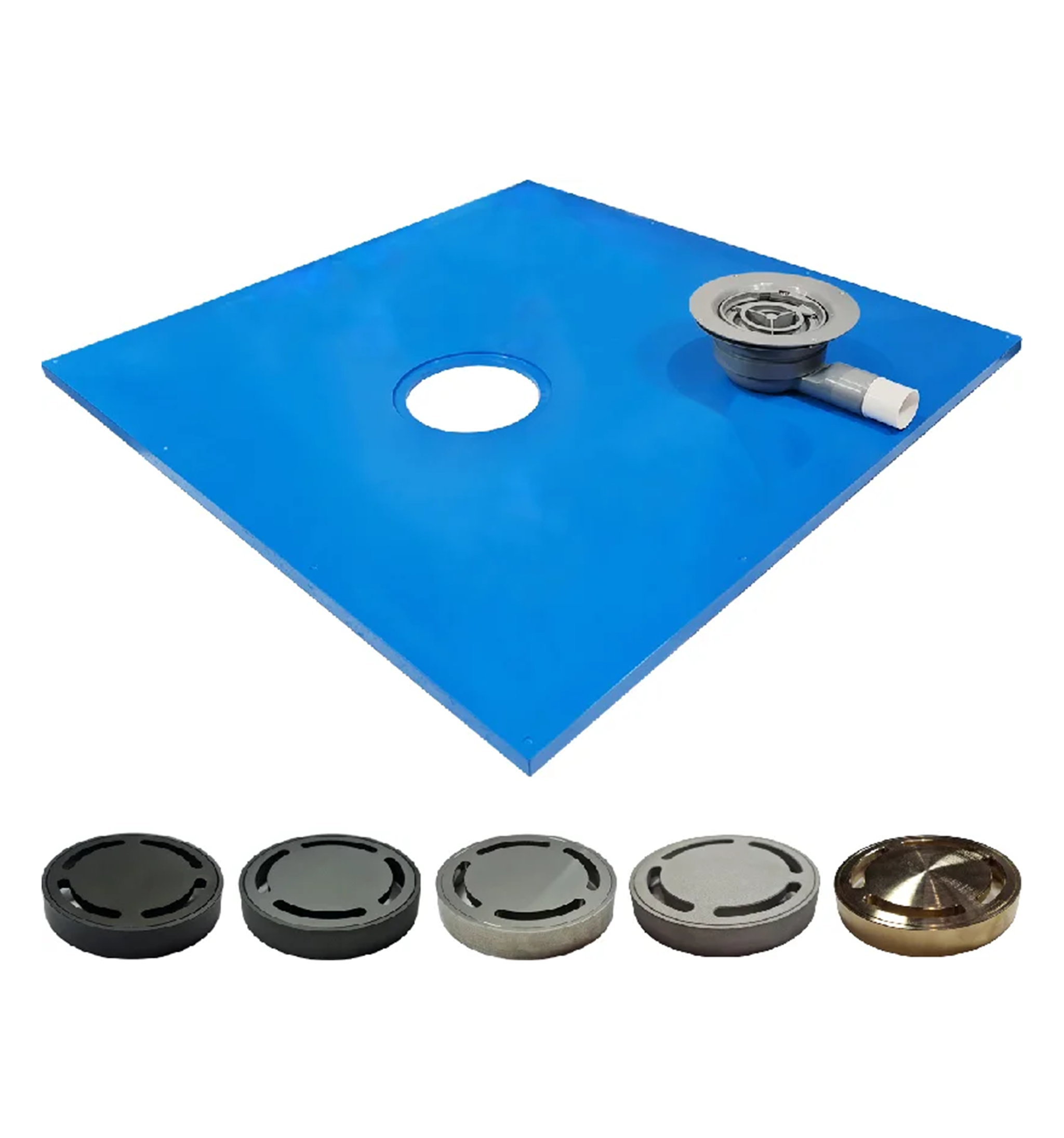

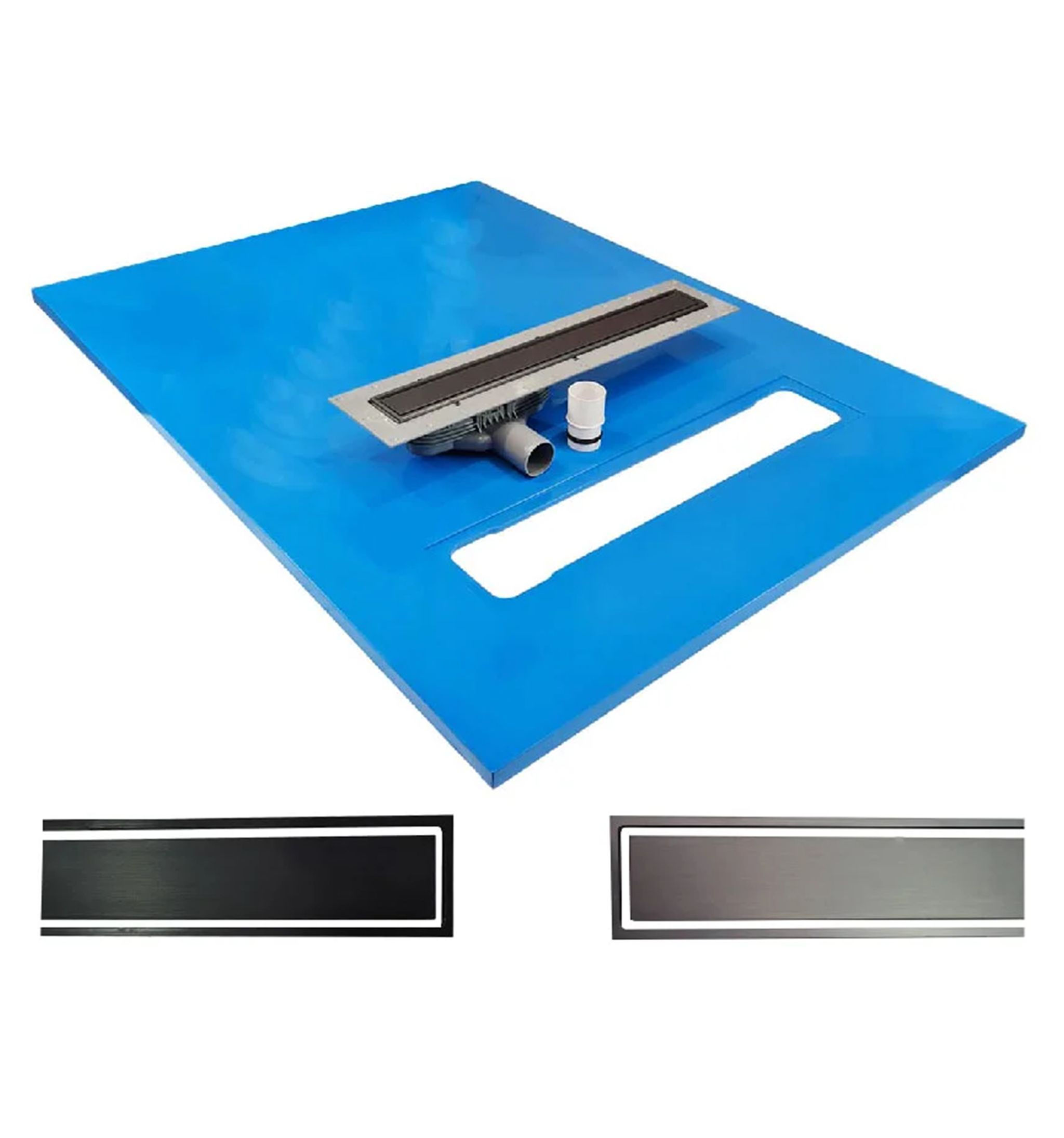

| Shower Tray Compatible | Yes | Yes |

| Available Colours | 30 | 20 |

| Mood board Set Available | Yes | No |

| Colour Matches Available? | Yes | Yes |

| Visual Appeal | Easy to discolour during application, great for visibly textured finishes. | Ideal for more seamless, undisturbed finishes due to higher resistance to burnishing. |

| Sizes | 5sqm, 10sqm | 10sqm |

| Sample Kit available? | Yes | Yes |

| Price of Full Kit (10sqm With Anticrack) | £450 VAT INC | £540 VAT INC |

The Continuo Application

Surface Preparation

Ensure the substrate is solid. The surface is smooth and has been prepared without any cracks. There should be no dust or any particles, so that the primer can adhere adequately.

Primer Application (1+ coats)

The correct primer can now be applied to the surface. Atomo is the most common primer, which is usually used for porous surfaces. In the event of applying on a non porous surface, Prolink would be the correct primer.

The Anticrack System (2 Coats)

The Anticrack system should be applied, depending on the substrate. This is essentially a basecoat with embedded mesh, that is used to prevent the Microcement from cracks due to movement of the substrate.

Decorative Coat (2 Coats)

This can be applied both on top of the basecoat if the Anticrack was used, or directly onto the primer if the anticrack was not used. These 2 coats of plaster will create the finish that will eventually be your surface. A good eye for details and technique is required in order to achieve something even, consistent and beautiful.

The Link (1 Coat)

Link is a pre-sealer, this means it works almost like a primer for the resin protector. Link is designed to penetrate the decorative coat, and seal its pores. Link will change the colour from that of the plaster, by making it a little deeper. This is why, a Microcement sample can only be presented accurately, when the Link coat has been applied.

The Top (2 Coats)

Continuo Top is the main resin sealer used to protect a Microcement surface. Available in Matt, Satin or Gloss, this sealer will form a layer on top of the Microcement, that is non porous, and resistant to water.

Continuo Microcement

Continuo has stood the test of time. Its natural, comforting colours and array of application methods, make it the first choice for new, as well as seasoned applicators. This has made our microcement courses the most popular choice within our range.

The Continuo range has been sold at Impera Italia for over 5 years. This is a relatively long time for a Microcement system in the UK. In this time, it has proven its reliability and workability. It is admired by applicators for the freedom it affords sits applicators to design truly incredible spaces.

The All Over Application

Surface Preparation

Ensure the substrate is solid. The surface is smooth and has been prepared without any cracks. There should be no dust or any particles, so that the primer can adhere adequately.

Primer Application?

The All Over Micro coating does not necessarily need a primer before it is applied to porous substrates. The plasters that form the basis of this material are better at adhering to surfaces. In the even of applying on a non-porous surface, Prolink Primer should be used.

The Anticrack System (2 Coats)

Much like the Continuo, All over has its own Anticrack system that should be applied on to floors each and every time. On walls however, it is possible to apply only the basecoat for a textured finish, or only the finishing coat for a smooth finish. This means that All Over can technically be applied in 4 layers!

Decorative Coat (2 Coats)

This can be applied both on top of the basecoat if the Anticrack was used, or directly onto a primed, or un-primed substrate if the anticrack was not used. These 2 coats of plaster will create the finish that will eventually be your surface. A good eye for details and technique is required in order to achieve something even, consistent and beautiful.

The Link

All Over does NOT require a link coat, meaning this step is skipped entirely.

The Top (2 Coats)

Although All Over has its own mono-component sealer, Our tests show that the Continuo Protector is still the preferred solution. This also gives the choice of Matt, satin & Gloss. The All Over protector is only available in Semi-Matt

All Over

The All Over system, is a brand new, Micro coating system designed to be faster and easier to apply, whilst providing the same excellent advantages of the Continuo range.

All Over makes it easier and faster to carry out a project. This fantastic material, one of the most advanced in the industry, is strong, durable, and less prone to mistakes and wastage. All Over is also better suited to very seamless, uniform finishes that blend large spaces into endless canvasses of colour and texture. An absolutely winner in the world of minimalistic interior design.

Applying Microcement In Bathrooms

Microcement is a multi-layer coating system with several qualities that make it suitable for bathroom and wet room applications. The seamless, water-resistant finish is a visually appealing choice that offers functional and aesthetic benefits over tiles.

Why is a Microcement Bathroom a good choice?

1.It’s an Aesthetic and Versatile Surface Solution

For a bathroom with a minimalistic, contemporary appeal, no surface finish could compete with Microcement when it comes to versatility.

The multi-layer system includes a decorative coating that can be coloured to any bespoke choice, and applied in various different textures. Our Continuo Microcement system is also available with different protecting coats, offering you a matt, satin or gloss finish, to further customize your Microcement surface.

To explore our neutral and bright colour selection for Microcement, click here!

If you have a specific colour in mind and need a bespoke option, book a colour match service here!

2.It’s Durable and Water-Resistant

Thanks to its different components, the Microcement system’s different layers work together to ensure a durable and water-resistant finish. This makes it suitable for bathrooms, as it will also withstand moisture and humidity.

What makes Microcement water-resistant?

A proper application of each component will make the finish water-resistant.

This starts by using the right primer, to ensure the base coat can adhere to the substrate, whether that’s a porous or non-porous surface. With the base, a mesh is also applied, which together will form an anti-crack system, that prevents any cracks on the surface.

Once the base coat is applied, the decorative coats follow, which will provide an aesthetic finish and texture.

The final coat includes the sealers and protectors, which create a water-resistant surface that is also able to withstand the daily wear-and-tear the surfaces are exposed to.

Due to these qualities, Microcement can be applied anywhere in a bathroom, including the shower area, vanity tops, floors and walls.

If you are interested in the full process of the Microcement application, check out this tutorial!

The Maintenance of Microcement

Maintaining these surfaces is more simple than it seems. Regular cleaning with mild detergents and protective measures are very useful and simple steps to take, to ensure the longevity of the finish.

Periodic resealing is recommended to keep the surface for it to maintain its waterproof qualities, and preserve its original look. A Microcement shower is likely to only need mild wiping down with soap and water regularly. A Micro cement floor however, is likely to need a slightly more abrasive chemical. CIF cleaner would be our best recommendation. This can also be used to clean a microcement worktop kit. The maintenance steps can vary depending on which Microcement you used, and what surface was it applied on. For our Microcement, we recommend resealing every 5-10 years.

Maintaining microcement in bathrooms is straightforward. Regular cleaning with mild detergents and water is typically sufficient to keep the surfaces looking new. Periodic resealing is recommended to maintain the waterproof properties and prolong the lifespan of the microcement.

Conclusion

There are several reasons that make Microcement suitable for bathroom applications, both aesthetic and functional. The seamless, durable finish it provides makes it a popular choice for wet room areas, where there is a growing demand for bespoke finishes that create a visually appealing design for residential and commercial properties as well.

A professional application and regular maintenance make it a great choice for stylish bathrooms, that can stand the test of time.

Applying Microcement on Floors

In short; yes. Microcement is a great choice for flooring, as it provides numerous advantages. Its seamless look and versatile options made it a popular design choice in the last few years.

So what are the main reasons Microcement is a fantastic option for flooring?

Here are 4 reasons why you should consider having it installed in your home!

1. Aesthetic and Design Flexibility - an easy way to personalise your home.

Microcement is known for its sleek and modern appearance, which complements residential and commercial space with a similar aesthetic. But it doesn’t stop here.

As Microcement is a multi-layer coating system, it has a decorative and a top coat that can be personalized. This means you can have it in virtually any colour, texture and finish. This means it can also be a great choice for a wide range of interior styles.

To test the different neutral and bright colours we offer, click here!

To get a bespoke colour, book a colour match service here!

2.Durability and Maintenance - a finish that will stay with you for years to come.

Having a resin coat, as its final protecting coat, Microcement can withstand a lot. From daily wear-and-tear to small scratches, even stains (if not left for too long). This ensures that the beautiful bespoke finish you chose will stand the test of time, and be exposed to daily life.

With regular cleaning and periodic resealing, your Microcement flooring will preserve its original look for a very long time.

For technical details and tips to maintain our Microcement, send us an email to sales@imperaitalia.com!

3.The Application Process - that will save you both time and money.

Microcement as a flooring option is not only durable, but it’s also very practical. As it can be applied over existing surfaces, there is no need to remove any tiles or wood, you just need to the appropriate primer. Due to its nature as a multi-layer coating system, the application of Microcement includes several different steps that ensure durability.

What are the different steps of applying Microcement?

Surface Preparation: The existing floor must be clean, dry, and free of debris. Any cracks or uneven areas should be repaired.

Priming: A primer is applied to promote adhesion between the substrate and microcement.

Base Coats: A base layers of microcement with or without mesh is applied to create a stable foundation.

Finishing Coats: The final layer provides the desired texture and colour.

Sealing: A protective sealant and sealer is applied to enhance durability and water resistance.

If you are interested in learning more about the application of Microcement, check out our beginner and advanced courses.

4.Environmental Benefits - reduce waste and preserve your home’s air quality.

There are several reasons why Microcement could be a good option for those concerned with the sustainability features of their products.

Depending on the supplier, the composition of microcement can differ and therefore, so is its effect on indoor air-quality. Our supplier, San Marco, as an established figure in the decorative industry, ensures they have extensive testing and product development, to create products with the least amount of harmful chemicals. For certifications and specifications, check out the Continuo and Allover datasheets, each available on their respective product pages.

Its other important sustainability feature is that it can be applied over existing surfaces, reducing waste and the thin layers ensure a minimal raw material consumption.

Conclusion

Microcement is a fantastic choice as a flooring option, due to its practicality and aesthetically pleasing look. It offers a beautiful seamless finish, which can be customised according to taste and a wide range of interior styles.

The easy maintenance and the bespoke looks that can be created made Microcement one of the most popular choices as flooring, and we suspect it will win over even more design lovers in the future!

Can Microcement Be Used With Underfloor Heating

Yes, it is possible to use microcement with underfloor heating systems. One of the many reasons it is a popular finish is its compatibility with underfloor heating systems, which is becoming a standard for many modern homes and even commercial places.

We have listed some of the important considerations for using microcement with underfloor heating.

Benefits of Using Microcement with Underfloor Heating

Thermal Conductivity:

Due to its excellent thermal conductivity, it can transfer heat efficiently from the underfloor heating to the surface. This means even and comfortable temperature distribution across the surface.

Flexibility:

Due to the composition of Microcement, as a coating system made up of different components, the different binders and polymers in the material allow for it to withstand the expansion and contraction caused by temperature changes, and thermal stress.

Seamless Finish:

The seamless finish it creates on the surface, and the absence of grout lines and joints, ensures consistent temperature across the floor.

Thin Application:

Due to its nature as a product, Microcement can be applied in very thin layers, which is usually around 2-3 mm, which means quick and efficient heat transfer and warming of the surface. This is also very practical for projects where the floor height is a concern.

Installation Considerations

Proper Substrate Preparation:

To ensure the material is applied properly, the minimum thickness of the screed and any substrate over the underfloor heating need to be double-checked with the manufacturer.

The substrate has to be stable and free of any cracks, as any movement can lead to issues with the Microcement, especially when combined with the changing temperatures it's exposed to with underfloor heating.

Insulation:

Adequate insulation of the surface before the installation of the underfloor heating system is crucial, as it ensures the heat will be directed upwards, rather than being lost.

Gradual Heating:

Thermal shock is a risk with underfloor heating, which can cause cracking on the Microcement surface. To avoid this, it’s important to increase the temperature gradually when it’s used for the first time and allow the material to acclimate.

Professional Installation:

Microcement in itself is a very technical coating system to apply, but when combined with an underfloor heating system it requires a deep technical understanding of both systems and professional experience, as even minor mistakes can create serious future problems.

Curing Time:

Without allowing adequate curing time for the Microcement, the underfloor heating should not be turned on. This usually means at least two weeks after the application of the final coat but may need to be more depending on the temperature, ventilation and humidity. Always double-check with the supplier.

Maintenance Tips

Temperature Control:

Keeping the temperature consistent, without setting it too high can help maintain the integrity of the microcement and avoid weakening of the material.

Regular Cleaning:

Maintaining the surface according to instructions and avoiding harsh chemicals are essential to ensure it maintains its appearance and longevity.

Conclusion

Microcement is an excellent surface solution to use in conjunction with underfloor heating systems, due to its good thermal conductivity. Its functional and aesthetic properties make it a competitive alternative for various surfaces, especially in wet room areas.

Professional installation and maintenance are key to ensuring that the material works well when combined with an underfloor heating system. By following the recommended advice, you can enjoy all the functional and aesthetic advantages of the beautiful, seamless finish.

For any advice about our Microcement Systems, be sure to contact sales@imperaitalia.com.

If you are interested in learning the professional application of Microcement, check out our beginner and advanced courses!

Applying Microcement On Stairs

Microcement is an excellent choice for covering stairs due to its durability, seamless finish, and versatile aesthetic options. A microcement floor is a highly impactful way to enhance a living space. Here’s a detailed overview of how to apply microcement on stairs:

Benefits of Microcement on Stairs

Seamless Finish: Microcement provides a smooth, joint-free surface, eliminating grout lines where dirt can accumulate.

Durability: It is highly resistant to wear, making it suitable for high-traffic areas like stairs.

Slip Resistance: When applied with a textured finish, microcement can provide a non-slip surface, enhancing safety.

Aesthetic Flexibility: Available in various colours and finishes, microcement can match any design style, from modern to rustic.

Application Process

Surface Preparation:

Cleaning: Thoroughly clean the existing stair surface to remove dust, grease, and debris.

Repairing: Fill any cracks or imperfections with a suitable filler and sand smooth.

Priming: Apply a primer to enhance adhesion. The type of primer depends on the substrate material (e.g., concrete, wood).

Base Coat Application:

Sets corner beads, if necessary, Apply the base coat with a mesh using a trowel, even layer (approximately 1-2 millimetres thick). Allow it to dry completely. Then apply second coat of base plaster.

Sanding: Lightly sand the base coat to remove imperfections and ensure a smooth surface.

Decorative Coat Application:

Mixing: Prepare the decorative coat, adding pigments if a specific colour is desired.

Application: Apply the finishing coat with a trowel to achieve the final texture and appearance. This layer determines the aesthetic and functional qualities, such as slip resistance.

Sanding: Lightly sand the base coat to remove imperfections and ensure a smooth surface.

Sealing:

Sealer Application: Apply a sealant and sealer to protect the microcement surface from stains, water, and wear. Multiple coats may be necessary.

Drying: Allow each coat of sealer to dry thoroughly. The sealer enhances the durability and ease of maintenance of the microcement surface.

Maintenance

Regular Cleaning: Clean the stairs regularly with mild detergents and water. Avoid harsh chemicals that can damage the sealer.

Resealing: Periodically reseal the stairs to maintain their protective layer and ensure longevity. The frequency of resealing depends on the level of use.

Conclusion

Applying microcement to stairs offers a durable, aesthetically pleasing, and low-maintenance solution suitable for both residential and commercial properties. Its seamless finish and customizable appearance make it an ideal choice for modern design projects. With proper application and maintenance, microcement stairs can provide long-lasting beauty and functionality.

By following these steps and using high-quality materials, you can achieve a professional and attractive microcement finish on stairs that enhances both the safety and visual appeal of your space.

Applying Microcement For Walls

If you came across seamless finishes, with a sleek and modern look, you may have seen Microcement walls. If that seamless look was in a bathroom or any wet room, you have definitely seen Microcement shower walls. A sample of our microcement Manchester colour is available inside a shower in our showroom to show this off! Many of our microcement bathrooms are completed in different styles. Where some clients may opt for a microcement wall finish only, some clients will also consider a microcement bathroom floor to enhance the minimalistic appearance of the space.

Microcement, is a multi-layer coating system, that can achieve uniform finishes on different surfaces, vertical and horizontal. Due to how flawlessly it fits in with modern interiors, it recently became popular amongst designers and homeowners alike.

So what makes Microcement a good idea for walls?

1.It’s an Aesthetic and Versatile Finish

Microcement is an aesthetically pleasing solution that offers a wide range of choices for customisations. The beautiful, seamless finish can be achieved in different textured or smooth versions, and the decorative coat can be bespoke coloured to match any style, whether it’s a subtle neutral or a bold and vibrant finish.

Microcement has gained remarkable popularity in the last few years, primarily due to its aesthetic appeal, and the fact that it can be made to fit any designer’s vision for a project!

To explore our neutral and coloured options for the Continuo Microcement range, click here!

2.It’s Durable and Easy to Maintain

The different layers and components that create the Microcement finish ensure that it will last, and provide a practical solution for a surface covering.

The final coat of resin makes Microcement an ideal choice for high-traffic areas in residential projects, such as hallways and kitchens, as it has excellent resistance to wear and tear. When maintained properly, it can last many years, but we recommend periodic resealing, to ensure the finish stays exactly as it was applied.

Due to the same layer, Microcement is also resistant to water, which means it can be applied to bathrooms, even the shower area, worktops and splashbacks.

To find out more about whether Microcement is suitable for your project, email sales@imperaitalia.com.

What is the Application Process, that ensures its durability?

As Microcement is a multi-layer system, the application technique is very specific for each product, but the main components and steps are usually the same.

Surface Preparation: The wall surface must be clean, dry, and smooth. Any cracks or imperfections should be repaired.

Priming: A primer is applied to enhance adhesion.

Base Coat: A base layer/s of microcement with or without mesh is applied to create a solid foundation.

Decorative Coats: The final layer is applied to achieve the desired texture and appearance.

Sealing: A sealant and sealer is applied to protect the surface from stains and moisture.

3.Environmental Benefits

There are several reasons why Microcement could be a good option for those concerned with the sustainability features of their products.

Depending on the supplier, the composition of microcement can differ and therefore, so is its effect on indoor air quality. Our supplier, San Marco, as an established figure in the decorative industry, ensures they have extensive testing and product development, to create products with the least amount of harmful chemicals. For certifications and specifications, check out the Continuo and Allover datasheets, each available on their respective product pages.

Its other important sustainability feature is that it can be applied over existing surfaces, reducing waste and the thin layers ensure a minimal raw material consumption.

Conclusion

Microcement recent popularity is no accident. The product offers such a wide range of benefits, from practical to aesthetic, that it seems like the perfect choice for more and more homeowners and designers. Its seamless finish and practical benefits will no doubt fit into almost any interior style.

If you are interested in checking our different Microcement Kits and Samples, click here!

Does Microcement Crack

Microcement, otherwise known as micro concrete or microtopping, is an increasingly popular material due to its versatility and seamless finish. As a construction material, however, it does have certain characteristics that are not ideal, for example, the risk of potential cracking.

However, as a complex system with multiple layers, it is good to understand what exactly could lead to cracking and what can be done to avoid it.

Here's a detailed look at whether Microcement cracks and what can influence this outcome:

Factors That Influence Cracking in Microcement

1.Substrate Condition:

Stability: Whether or not a substrate is stable enough for the Microcement application needs to be assessed by the applicator. If it is prose to movement or has larger existing cracks that can’t be repaired, it can after the microcement finish.

Preparation:

Adequate preparation of the substrate, including levelling, priming, the reparation of any damage and cleaning can make a big difference to the quality and durability of the application.

2.Application Process:

Mixing and Consistency: Following the exact ratios given in the instructions and making sure the mixture even and consistent without any lumps is very important, as it could lead to weakness in the structure of microcement.

Layer Thickness: Applying each layer evenly, without any extra material getting to certain parts is crucial to ensure even bonding and curing.

Curing Time: Leaving enough time for the curing process between layers also ensures the durability of the application, and not calculating enough time for that could lead to potential damage in the future.

3.Environmental Factors:

Temperature and Humidity: It’s important to ensure consistent temperature and humidity during the application and curing process, as it can impact the microcement’s performance, and cause shrinkage and cracks.

Thermal Expansion: Considering the expansion and contraction of the material is important to consider, and try to keep the application environment under control.

4.Structural Movements:

Building Settling: New buildings or renovations can experience settling, which may cause movement in the structure and result in cracks in the microcement.

Vibrations: Consider the vibrations that certain areas are subject to, to take precautions.

Preventative Measures

1.Professional Installation:

Microcement is a very technical product with a complex application process. Hiring experienced professionals, who know and understand the theoretical as well as the practical aspects of Microcement, is essential to ensure the system is applied correctly.

2.Proper Substrate Preparation:

If any damage is not fixed and repaired, there is a risk of it leading to weakness in the structure of the Microcement and cause cracking. A clean, stable and prepared substrate is crucial for a quality application.

3.Controlled Application Environment:

Ensuring consistent temperature and humidity levels will help with an even application, without any issues related rapid drying and thermal expansions or contractions.

4.Use of Reinforcement:

Adding an anti-crack system to the base coat will add strength and flexibility to the structure of microcement, reducing the likelihood of cracks.

Conclusion

Despite its functional and aesthetic properties, with Microcement there is a potential risk of cracking, especially if the preparation work was not done properly.

Understanding the factors that can lead to damage means that precautions can be taken, reducing the risk of any damage in the future. This means assessing and preparing the substrate, and following professional advice for the application of the material.

For any advice about our Microcement Systems, be sure to contact sales@imperaitalia.com.

If you are interested in learning the professional application of Microcement, check out our beginner and advanced courses!

On What Supports Can Microcement Be Applied

Microcement is multi-layer coating system, that is suitable for a wide range of surfaces, both for decorative and functional purposes. It can be applied on virtually any substrate, with the appropriate primer and adequate surface preparation.

Which different surfaces can Microcement be applied on, and how should you go about it?

1.Concrete

When it comes to applying Microcement on concrete surfaces, it’s important to distinguish between new and old concrete applications. For freshly applied concrete surfaces, it is crucial to ensure it is properly cured, and free of any dust and particles.

For old concrete surfaces, repairing any cracks and levelling the surface is a must before any Microcement application.

2.Tiles

Applying Microcement over tiles is possible, and often done during renovations where the removal of tiles would mean extra time and cost. Whilst the joints may need to be filled, Microcement can adhere very well even to non-porous surfaces with the right primer.

3.Wood

Different types of wood can also be covered with Microcement, so long as it’s securely fixed and dry. The appropriate primer should be used before the application, and imperfections should be repaired.

4.Drywall (Plasterboard)

As with other surfaces, Microcement can be applied to drywall directly after ensuring proper surface preparation and priming. It can be applied to both old and new drywalls, so long as instructions are followed to ensure proper adhesion.

5.Plaster

Different types of plaster require different preparation, especially if it’s a decorative plaster. Depending on the texture of the surface, or any kind of protection that was used beforehand, the substrate should be prepped and primed according to professional instructions, to avoid any negative effect it could have on the bonding of the material.

6.Cement Boards

Microcement can also be applied directly to fibre cement boards, so long as the right primer is used.

7.Stone

It’s important to distinguish between natural and engineered stone, as natural ones may require more extensive preparation in case it has any loose parts or flakes, which should be removed before the application of the primer. Engineered stones should be prepped similarly, ensuring a clean and stable surface for the application.

8.Existing Coatings

Microcement can also be applied over any existing coatings, such as painted or varnished surfaces, with adequate preparation. Painted surfaces are simple to prepare, as only imperfections should be fixed and the surface cleaned before applying the primer, whereas varnished surfaces may need to be sanded and dusted, to create a surface Microcement can adhere to.

Important Considerations

Surface Preparation:

Depending on the type of substrate Microcement is applied on, the surface preparation can differ but nonetheless it is an essential part of the application to ensure a long-lasting, quality finish.

Stability:

Assessing the stability of the substrate and making sure the surface is free from any movement is an important part of the preparation work, as the Microcement can crack otherwise.

Priming:

There are different types of primers for non-porous or porous surfaces, and using the right one is crucial for the adhesion of the base coat to the substrate. Always check with the supplier.

Conclusion

One of the most practical aspects of Microcement, and what makes it a cost-effective alternative compared to other surface coverings is the fact that it can be applied over various substrates. With the right preparation and adequate primer, the adhesion of the basecoat is possible without any harm to the quality of the final finish.

Be sure to check with the supplier in case you have any questions regarding the primer or the surface preparation.

For any advice about our Microcement Systems, be sure to contact sales@imperaitalia.com.

If you are interested in learning the professional application of Microcement, check out our beginner and advanced courses!

Can Microcement Colour Fade Over Time

Unfortunately, as with other coloured materials, time and exposure to certain things can take a toll on the vibrancy of the colour. To put it simply, the colour fading does not in any way affect the quality or the functionality of the finish, it’s simply the aesthetic aspect that changes, as the pigment in the decorative coat fades.

This, of course, can be an inconvenience, but if we understand the reasons why Microcement may lose its colour over time, we can mitigate these effects to some degree.

Factors Causing Colour Loss

1.UV Exposure:

Depending on the layout of the interior, and whether the surface is exposed to direct sunlight. Prolonged exposure to UV rays could degrade the pigments used in the Microcement. This is especially true if the sealer applied does not have UV-resistant properties.

Solution:

Opt for window treatment that protects against direct sunlight and UV rays. If possible, choose a sealer that has UV-resistant properties.

2.Chemical Exposure:

It’s good to be aware of the usage of harsh cleaning agents and strong chemicals, such as bleach or ammonia, that should not be used on Microcement surfaces.

Solution:

Using mild, pH-neutral cleaning products, such as Cif is the best way for overall maintenance, both for its functional and aesthetic traits. Any spills should be cleaned immediately.

3.Wear and Tear:

Depending on how high-traffic the area is the intensity of the daily wear and tear can vary. These areas may need to have more frequent maintenance, as they are more prone to abrasion, which can cause the surface to lose its colour over time, and compromise the integrity of the finish if the top layer is damaged.

Solution: Introduce protective measures such as rugs or furniture pads to minimise the damage, and reseal the surface periodically to ensure it maintains its original look.

4.Moisture and Humidity:

Proper sealing is essential, as it can lead to damage on all Microcement surfaces. Unfortunately, when it comes to any damage in the sealer in spaces where the finish is exposed to moisture and humidity, it can lead to discoloration or efflorescence (a white, powdery deposit).

Solution: Regular cleaning and maintenance will ensure the water-resistance capabilities of the finish stay intact, and prevent moisture-related issues.

5.Improper Maintenance:

Failing to maintain the surface, especially the sealer can result in damages on a different scale but it can at the very least accelerate colour loss. This could be due to harsh cleaning detergents or tools, and possible spills of strong chemicals.

Solution: Always double-check the recommended maintenance with the supplier, and try to avoid cleaning tools or products that could negatively affect the surface.

Preventive Measures

1.Regular Maintenance:

Ensuring consistent cleaning with mild detergent, instead of using something harsh every now and then can go a long way in increasing the longevity of of the finish. Periodic resealing is always recommended, but it’s a good idea to inspect the sealer from up close, for signs of wear or any damage.

2.Quality Products:

Whilst quality microcement has a higher upfront cost, in the long run, it is worth the investment as it can withstand a lot more than low-quality materials. Quality components will help increase the longevity, durability and aesthetic appeal of the material.

If you want to see our range of Microcement mood board sets, with all the different neutral and standard colours applied, clickhere!

3.Professional Application:

Microcement is a very technical product, with multiple layers and components that need to be mixed and applied carefully. It is very important to have it done by a professional who is trained in the specific Microcement that is being applied, as a proper application technique is crucial to ensure the aesthetic appeal and functionality of the product is not compromised.

Conclusion

Microcement is a durable material, but as with any surface finish, it can lose its original appeal with time if not maintained properly. This means potential damage to the sealer and the fading of the colour pigments over time.

It’s important to consider the effects it’s exposed to on a daily basis, and ensure preventive measures are taken as much as possible. By following the guidelines of the supplier, and maintaining the Microcement properly, you can ensure that the vibrancy and durability of the products are maintained.

Is Microcement Difficult To Apply

Microcement, as a multi-layer coating system, can get very technical when it comes to the application, which would be challenging for anyone who has not worked with it before. Some compare it to Venetian plaster, and whilst their decorative coat is similar, Microcement has very specific instructions that ensure a durable and water-resistant finish, whereas Venetian plaster only serves decorative purposes.

We would only recommend trained professionals to apply it, as even small mistakes can cause big damages, and affect the functionality and longevity of the finish.

Why is Microcement more difficult to apply than Venetian plaster?

Here’s a breakdown of everything to consider when applying Microcement.

Preparation

Quality application starts with adequate surface preparation, and assessment. Depending on the the substrate, our Microcement comes with different primers, one for porous and one for non-porous surfaces. This ensures corect bonding of the material to the substrate, and prevents future damage.

It’s also important to ensure the substrate is clean, and even, and any imperfections are fixed.

Tips for Priming:

Double-check if you have the right primer for the substrate.

Let the primer dry completely, before continuing with the base coat.

Application

Tips for Mixing and Applying:

Follow our the exact mixing ratios.

Pay attention to the and instructions of the each component of the Microcement, always double-check and only mix what you’ll be able to use in a few hours, as some components start to harden right away.

Mix each component’s A and B thoroughly, ensure there are no lumps left.

Use the right tools, and use them carefully as the decorative coat can easily be burnished and create unwanted marks.

Follow the instructions, but don’t hesitate to ask us for advice before applying each coat or if you think something is not right. You can reach our Showroom at 0333 012 4396 between 8AM - 5PM, Monday to Friday or via our email, sales@imperaitalia.com.

If you took a course with us and would like a refresher, check out our full tutorial here!

Finishing

Tips for Sealing:

The final coat should be dry before applying the sealer.

Apply at least two coats of the sealer, and wait enough for it to be completely dry before any contact with water.

For Microcement applications, it will take a few days before it reaches maximum hardness and water resistance, therefore the waiting time after the application is crucial.

What to Consider When Applying Microcement?

Time and Patience:

Microcement needs a considered and careful application in order to benefit from the functional and practical benefits it offers. Plan enough time for the application, and don’t rush the process as each layer needs to be carefully applied and left to dry.

Skill Level:

We recommend that only people trained in the Microcement application apply it, as surfaces exposed to water can be damaged easily if the application was not done correctly.

To learn the application of Microcement, check out our beginner and advanced courses!

Quality of Materials:

Choosing a high-quality Microcement is crucial to get the finish and results you are after. Our Microcement, supplied by San Marco, has been developed and rigorously tested by one of the most established manufacturers in the industry and countless happy clients and applicators have nothing but good to say about the material.

Check out our Allover and Continuo Microcements!

Conclusion

The application of Microcement is quite technical, therefore, it is best left to people who have been trained to apply it or have extensive experience.

Aside from selling the material, we provide training for Microcement for beginner and advanced applicators as well, to ensure each project is a success!

Applying Microcement In High Temperatures

The application of Microcement is a technical process, that requires knowledge and skill. However, when the ideal circumstances are not guaranteed, such as temperature, it can affect the quality and durability of the finish regardless of the skill of the person applying it.

However, it is not impossible to achieve a proper application of Microcement, even without the ideal temperature.

So how is Microcement applied at high temperatures, and what advice do we have to achieve an ideal finish?

The Ideal Temperature Range

What is the ideal temperature to apply Microcement? Generally, between 15°C and 25°C. When the temperature exceeds this range, special precautions need to be taken.

What issues can arise when applying Microcement at a high temperature?

1.Rapid Drying and Curing

Certain components start to harden as soon as they are mixed, and this is further exacerbated by applying it at a higher temperature. This can result in a patchy, uneven finish or even the cracking of the material due to moisture loss.

2.Workability

If the material starts hardening and cure before we had a chance to get an even application, it can be very challenging if not impossible to fix. Unfortunately, without any precautions taken, the material may become thicker and harder to spread, which will affect the quality and durability of the application.

3.Adhesion Problems

If the temperature is too high during the application, it can affect the bonding of the material to the substrate, and between different layers.

As the heat can cause the substrate to expand, it may affect the adhesion of the base coat to the substrate, which can lead to peeling and delamination over time.

What precautions do we recommend before applying Microcement in high temperatures?

Good Timing:

The best is to avoid applying the material during the day, to avoid peak heat. If possible, start early in the morning or late afternoon. Avoid working under direct sunlight, as it can overheat the substrate, leading to a much quicker drying time for the material.

Surface Preparation:

If needed, adequate surface preparation can also help when applying microcement at high temperatures. Try to dampen the surface lightly, before the application as this will prevent the basecoat from drying too quickly.

This, however, should be done with caution, as too much moisture can affect the adhesion.

Mixing Adjustments:

When mixing the different components of Microcement, use cool water for the mix to help lower the overall temperature of the material.

Protective Measures:

If there is direct sunlight, try creating a shade over the working area to prevent the substrate or the material from overheating, and avoid sudden heat exposure.

Hydration Control:

To keep the surface moist, and avoid it drying too quickly, try misting some water on it during the initial curing period. This could be an important step to prevent rapid drying and cracking.

To control the curing environment, try using a curing blanket or plastic sheeting to help the surface retain moisture and dry gradually.

Equipment:

Tools and equipment used for the application should all be cool before use, as even hot tools can accelerate the drying of the components.

Conclusion

Applying Microcement at high temperatures is something to be taken seriously, and precautions need to be taken to ensure a high-quality finish.

Preparing the surface, planning ahead and using protective measures to control the environment and help mitigate the adverse effects of heat.

Follow these tips to make the most out of the micorcement, by achieving a smooth and durable finish.

If you have not worked with Microcement before, book our beginner course to learn a new in-demand skill!

If you have some experience but want to take your knowledge to the next level, try our advanced course!

Applying Microcement In Low Temperatures

The application of Microcement is a technical process, that requires knowledge and skill. However, when the ideal circumstances are not guaranteed, such as temperature, it can affect the quality and durability of the finish regardless of the skill of the person applying it.

However, it is not impossible to achieve a proper application of Microcement, even without the ideal temperature.

So how is Microcement applied at low temperatures, and what advice do we have to achieve an ideal finish?

The Ideal Temperature Range

What is the ideal temperature to apply Microcement? Generally, between 15°C and 25°C. When the temperature exceeds this range, special precautions need to be taken.

What issues can arise when applying Microcement at a low temperature?

1.Slower Curing Time

When applying Microcement at temperatures below 15°C, the curing of the material slows down significantly. The extended curing time could affect the strength and durability of the final finish.

2.Increased Risk of Cracking

As low temperatures can cause the water to freeze, the water in the microcement mix can have some ice crystals forming. This can lead to serious structural issues, which can contribute to the material curing improperly and cracking later.

3.Adhesion Problems

If the temperature is below the ideal range for Microcement application, it can affect the adhesion of the base coat to the substrate, which can lead to delamination.

4.Condensation Issues:

The high humidity, combined with low temperatures can lead to condensation on the substrate and moisture on the surface, which could prevent proper bonding of the material.

What precautions do we recommend before applying Microcement in low temperatures?

Indoor Applications

When working on indoor applications, the space should be adequately heated to maintain a temperature above 15°C

for the entire application and curing process. Depending on the space, heaters can help achieve the necessary conditions.

Heated Substrates

If possible, it’s a good idea to pre-warm the substrate and help prevent the issues that could arise from cold surfaces. This can be done using heating mats or blankets designed for construction use.

Extended Curing Time

It’s better to wait longer and avoid rushing the process, allow enough time for each layer to be completely dry before applying the next one.

Use of Additives

Certain additives can be mixed with Microcement to help the application process by accelerating the curing time and improving adhesion.

Protective Measures

If possible, Microcement should be protected from cold drafts and sudden temperature changes. This can be done by using temporary enclosures or tarps, which can help maintain a stable environment.

Conclusion

Ideally, Microcement should be applied between 15°C and 25°C, but if the temperature falls lower than this range, precautions should be taken to ensure it won’t the affect quality of the application. Regulating the temperature with the appropriate heating methods and allowing enough time for curing is key to achieving optimal results.

Be sure to check the technical details of the microcement with the supplier.

If you have not worked with Microcement before, book our beginner course to learn a new in-demand skill!

If you have some experience but want to take your knowledge to the next level, try ouradvanced course!

Is Microcement Durable

Microcement is known as a durable surface finish, that provides a seamless look and a wide range of options for a bespoke finish.

But what exactly makes Microcement a durable material? Here are 7 key elements that contribute to its longevity

Factors Contributing to the Durability of Microcement

Composition

As a material composed of cement, polymers and fine aggregates, it’s a robust and resilient material. The added polymers enhance the flexibility and adhesion, ensuring a finish less prone to cracking than traditional cement.

Adhesion

Due to its excellent adhesive properties, Microcement can be applied on virtually any substrate. With the right primer, it can can bond well to anything from tiles to wood, and create a durable finish. This also means a practical advantage when it comes to the installation of the product, as it can applied directly to the substrate, without having to remove it.

Resistance to wear and tear

As a final coat, Microcement has a resin protector applied, which prevents small scratches and marks on the surface. As long as its maintained properly, Microcement is resistant to daily wear and tear, which makes it suitable for worktops, floorings and bathrooms as well.

Resistance to water and stains

The protector included in the Microcement Kit makes the surface resistant to water, and prevents other liquids from penetrating the surface. It’s a popular choice for Kitchen worktops, as the protective layer ensures durability, even for practical surfaces.

For practical advice on maintaining microcement, please refer to the product page or email us to sales@imperaitalia.com.

Thermal Resistance

Microcement can not only handle higher temperatures on the surface, such as with a microcement kitchen worktop, but it can also be applied to underfloor heating. The heat resistance ensures the surface remains intact, without any cracking or deformation. That is also why a Microcement kitchen is a good idea!

Easy Maintenance

For maintenance, Microcement requires nothing more than a non-abrasive cleaning product and regular cleaning. The seamless finish and the absence of grout lines also ensures that limescale and dirt won’t accumulate there.

Aesthetic longevity

The aesthetic appeal of microcement can be maintained over time with proper care. It does not fade easily and retains its colour and finish, contributing to its long-lasting visual appeal.

Applications Demonstrating Durability

Residential Flooring and Walls

Given its aesthetic look and remarkable durability, Microcement is a popular choice for residential projects, where a modern and stylish appearance is key.

Commercial Spaces

Microcement is durable enough to be applied in commercial spaces, such as offices, restaurants and retail stores. Depending on the foot traffic and chemicals that is will be potentially exposed to, it’s best to double-check with the supplier, whether that specific type of microcement is suitable for that particular space.

Bathrooms and Kitchens

The resin dealer not only ensures protection against daily wear and tear, but it also protects against moisture and mild stains, making long-term maintenance easier.

Conclusion

Microcement is a well-suited material for a variety of applications, due to its sophisticated composition, and each layer has its own quality to ensure a durable and aesthetically pleasing finish.